The development started on the 16th May, 2006.

I chose an original ‘Vespa’ casing and fixed it on a 3D-measuring device, to measure all the boreholes.

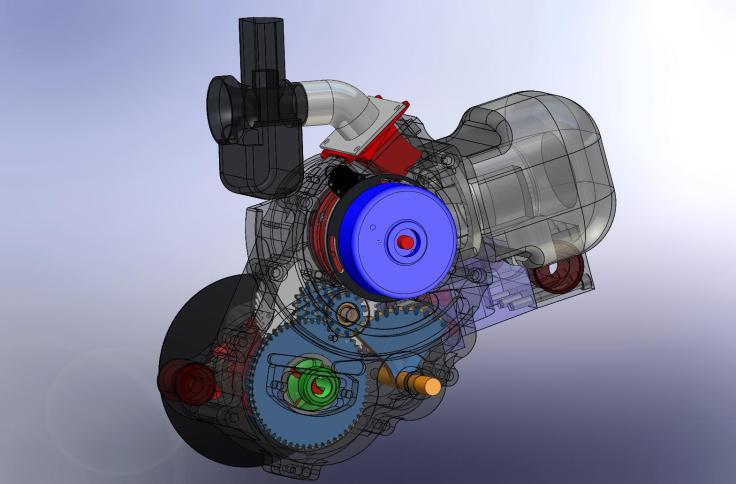

Then I sat in front of my CAD workstation for 8 weeks and constructed the whole casing.

Afterwards I milled two blocks from the solid and made a lot of tests with them.

A lot of things had to be changed, for example the air-cooling had to be replaced by a water-cooling system and the size limit of overflows that can be milled is nearly derestricted now.

I designed the alternator in a way that makes it even possible to use different ones. You can take the original one, the T5, with an adapter you can use the MVT Millennium and it is also possible to use inside rotor alternators. The choice is yours.

Taking the alternator without light access for the racetrack or the one with access for the street.

Additionally, the engine has a modified gearbox main shaft. There is a third bearing to prevent distortion.

At the moment I am trying to finish some sand cased casings.

The German “TÜV” has also been involved during the whole construction and development phase. The construction was authorized and the Scooter has the “TÜV” permit to drive on the street.

Pros:

– upright standing carburetor

– take what you want and place it into the membrane casing

– chose the cylinder you want

– chose the clutch you want

The finished engineering progress:

The milling progress: First programming the tool path and then simulate the whole milling action on the pc. Then the milling in the ureol. Afterwards trying the program on the aluminium block…

Hello Felix, I found your project through GermanScooter Forum and it is awesome, congratulations. My name is Vaggelis and I’m from Greece and of cource member of Greek Vespa Club. We do making some interesting projects here with vespa tuning, but not so extreme like yours. I do not know German so I hardly understand some things from the forum but the photo was very good. So my question is at first how much will it cost to have one of your CNC Engine. Do you have a version with rear disk brake? What cylinder kit can I use, only liquid cooled?

Regards, Vaggelis

Amazing work! Well done!

Hi Felix.

All highly tuned PX motors crack where the Xmas tree axle enters the cases, and fastened by a M9 nut. Looks like you’ve not added any extra material here? Has your begun to crack with all that power as the primary tries to dive the gears apart ? Mine cracked with just 18 RWHP, I added some material during repair, then tuned to an easy 23RWHP and have stopped there for the life of the cases.

Hi Nick, there is a lot more material at the Xmas tree axle.

If it cracks at 18PS there is something wrong…